info@bwtec.com +41 44 863 70 70

2451 TRACK TESTER

2451 TRACK TESTERDownload .pdf

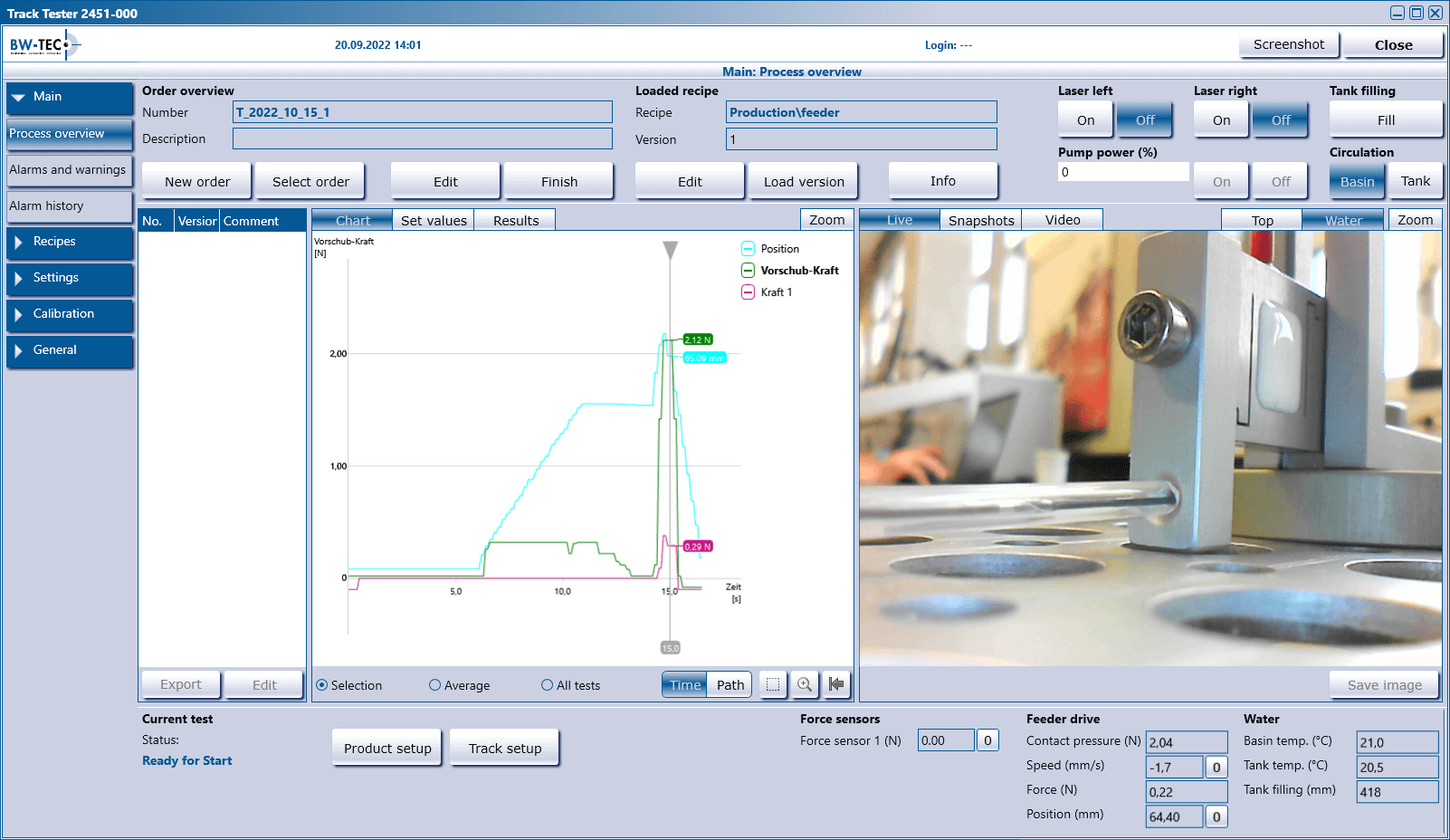

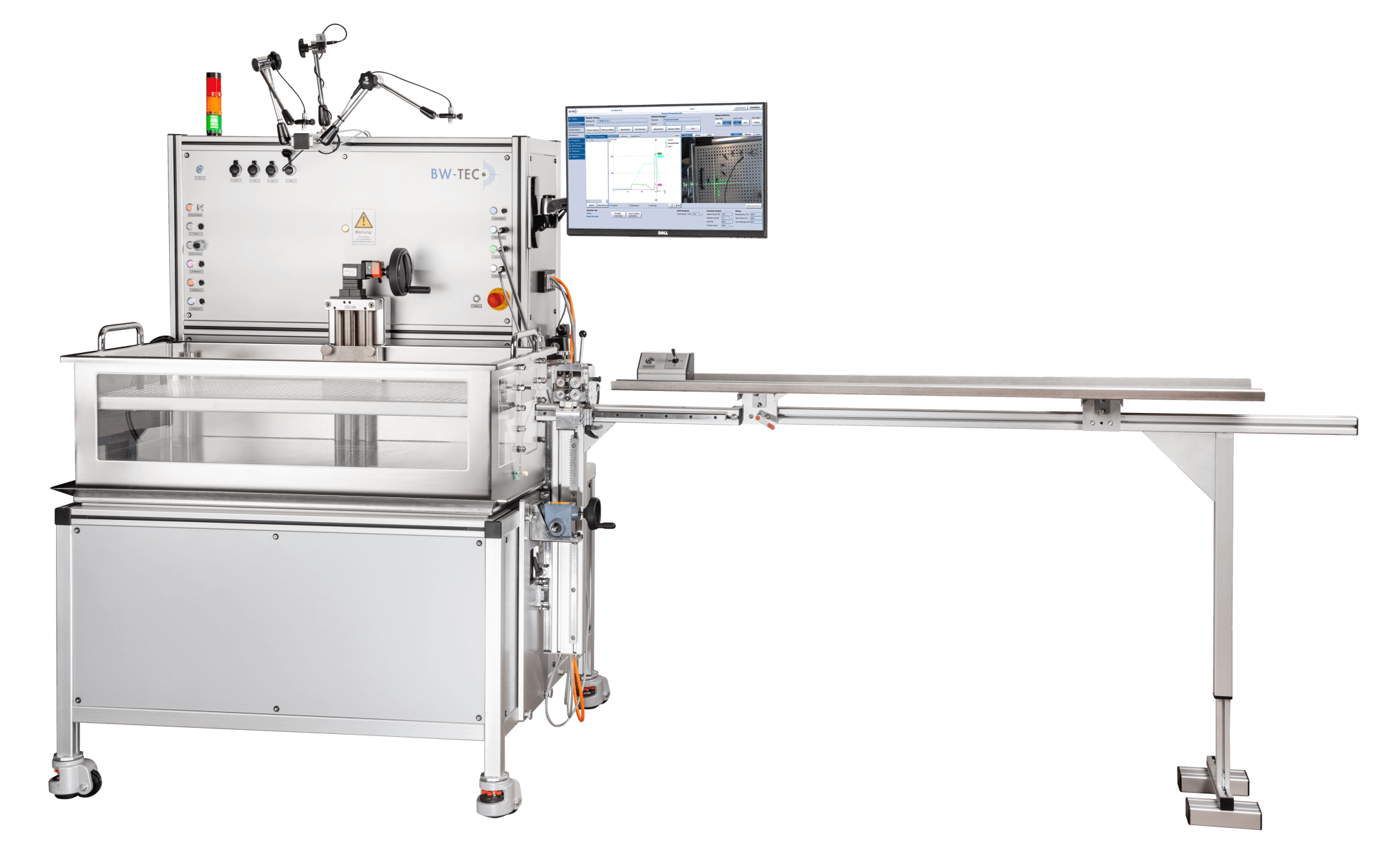

The 2451 Track Tester is designed to test and record the mechanical properties of guidewires and catheters in a water bath at body temperature. The machine impresses with a flexible recipe design, recording and storing of data. The proximal roller or torque assembly and the sensors can be selected and programmed as required. The recipe management is used to define the customer specific test sequence. The track setup can be equipped with a pump including flow measurement and additional tools can be added. The movements can also be performed manually with a joystick. A camera as well as an underwater camera record the process.

- bending / kinking

- push ability / push efficiency

- torsional strength

- stability of the connections against twisting

- guide ability

- applied force on a simulated vessel wall

- other evaluations such as averages of multiple tests, automatic multiple runs of the same test and more

Track force – Measures the force needed to advance a catheter, guidewire or other interventional device through a tortuous path using the recommended accessories.

Pushefficiency – Uses the proximal and distal load cells to measure the amount of force on the distal tip of the product when a known force is being applied to the proximal end of the product.

Flexibility – Measure of a catheter tip’s ability to track over a specified bend in a guidewire, such as a 90-degree bend.

Torqueability – In a tortuous path, measure of the rotational response at the distal end of a device while imparting a rotation at the proximal end.

Retractability – Measure of the force needed to withdrawal the device from a torturous path.

Crossability – Measure of the force needed to advance an endovascular system through a simulated stenosis/lesion within a tracking proximal end.

| Technical Specifications: | |

|---|---|

| Proximal Drives | |

| product range ø 0.5 - 5mm | |

| product feed with joystick possible | |

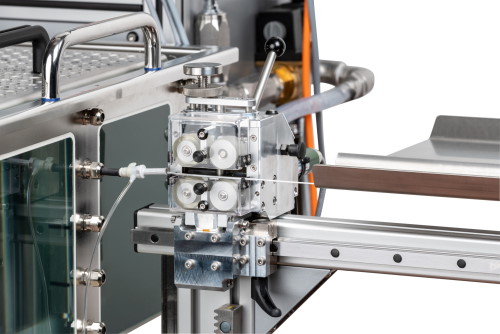

| Proximal Roller Assembly: • load cells: ±2kg, ±3kg or ±5kg • adjustable contact pressure with force display • encoder position feedback of 0.1mm • exchangeable rolls (PU or silicone) | |

| Periphery | |

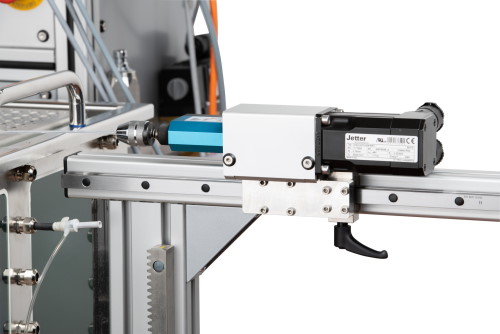

| 2x non contact laser position markers | |

| 1x top and 1x underwater camera for video play back with live forces | |

| Track (submersible) | |

| unit with pump and flow measure up to 3000ml/min with Luer Lock male | |

| 3 force sensors (±5kg, ±1 kg, ±100g) | |

| reaction torque sensor ±1Nm | |

| fixture for bending/kinking test with feeder unit | |

| Water (260L) | |

| water temperature 21 - 50°C ± 2°C (with auto start for heating and power save functions) | |

| advanced water treatment to maintain clean water for several months | |

| Handling | |

| user-friendly interface | |

| BW-TEC HMI on touchscreen | |

| PLC controller and PC for HMI and data management, network compatible | |

| General | |

| dimensions (L x B x H): 1700x 1550x 980mm (without table) | |

| weight 310kg (570 kg with water) | |

| power 3x230 VAC / 4000W | |