info@bwtec.com +41 44 863 70 70

2269 HYDROPHILIC COATING MACHINE

2269 HYDROPHILIC COATING MACHINEDownload .pdf

The Hydrophilic Coating Machine is used for coating of catheter production assemblies.

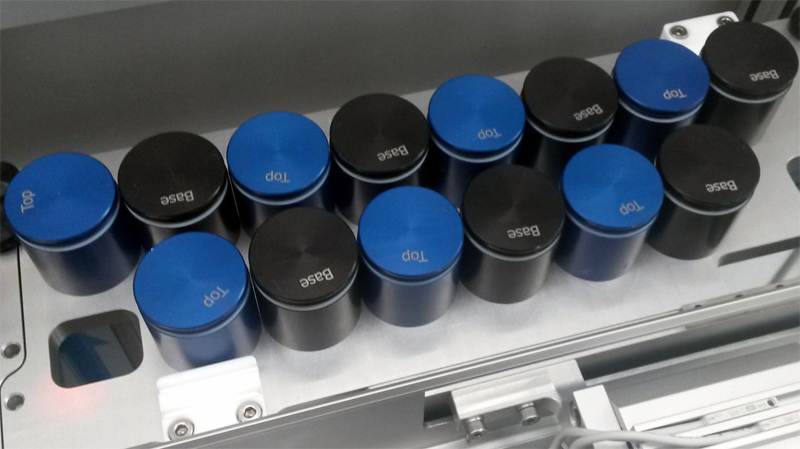

Up to 21 products are coated simultaneously by dipping and subsequent UV exposure in a controlled environment. A pneumatic system enables automatic switching between two rows of coating tubes (base coat and top coat). The machine is also equipped with a temperature and humidity sensor and two digital cameras to monitor the process.

This machine is equipped with a BW-TEC HMI, touch screen and PC for recipe management.

Option: Model 3010 BW-TEC Dip Coating with integrated 3D Curing Technology

Developed through a collaboration between Machine Solutions companies BW-TEC and Vela Technologies, this machine allows for the simultaneous dipping and curing of up to 12 products on a single rack, accommodating items of up to 500 mm in length. The system guarantees consistent UV radiation, thereby enhancing uniformity in the curing process across all products. Notable advantages encompass precise control over UV dose parameters for curing, elevated product uniformity, and substantial reductions in cycle times. This innovation stands as an efficient and effective solution for a wide range of dip coating and curing applications.

Equal Exposure for Enhanced Results

All surfaces are exposed to precisely the same amount of UV light, eliminating inconsistencies.

Streamlined Process

No rotation or lamp motion requirements.

Continuous Monitoring for Precision

Continuously monitors UV irradiation during the exposure process, ensuring unmatched accuracy and quality control.

Repeatability

Achieve repeatable exposure part-to part and batch-to-batch.

| Technical Specifications | |

|---|---|

| • simple user interface with the BW-TEC touchscreen HMI | |

| • can simultaneously coat up to 21 products | |

| • product rotation speed: 20 rpm | |

| • can change product immersion depth and speed in various sections | |

| • variable hold times and UV radiation times | |

| • repeatable top und base coating procedures | |

| • direct UV radiation for a product length up to 400 mm | |

| • easy to clean and reuseable bath systems | |

| • data connection and network management through an integrated P C | |

| • user administration with different operator settings | |

| • two digital cameras for active process viewing | |

| • magnetic product holders | |

| • bath axis: 500 mm | |

| • dimensions (L x B x H): 1500 x 1050 x 1990 mm | |

| • weight: ~500 kg | |

| • voltage: 3x 400 VAC 16A, 50/60 Hz, 3500 W | |

| • air pressure: 6 – 8 bar (0.6 – 0.8 M Pa) |