info@bwtec.com +41 44 863 70 70

2920 1UP NECKING MACHINE, SPLIT DIE

2920 1UP NECKING MACHINE, SPLIT DIEDownload .pdf

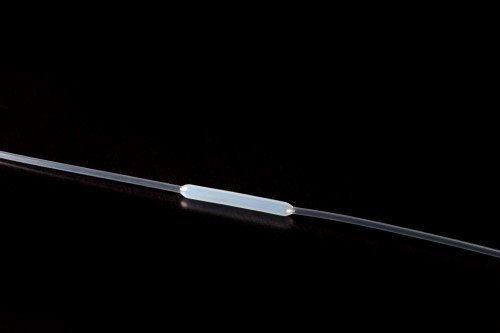

The 2920 Necking Machine is designed to neck down balloon tubes. This process step comes prior to the balloon forming process. The machine convinces with the capability of necking down small and large tubing.

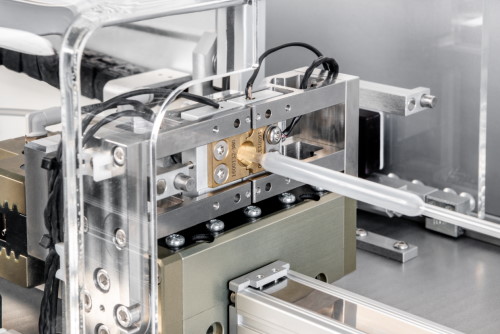

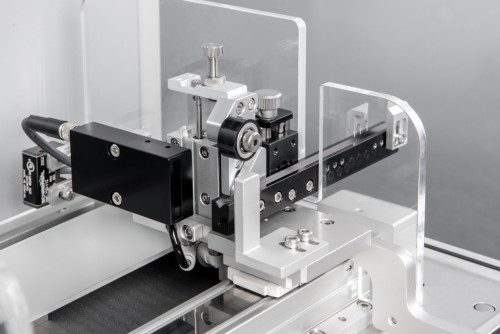

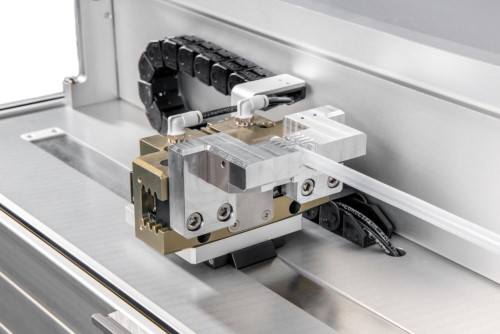

The tube is pulled through a heated die and reduced to a defined diameter. The die is split into two parts to enable easy loading. The final diameter of the tube can be changed by adjusting the following parameters: die diameter, temperature, speed and sensor position. The machine provides fast process time, defined necks and precisely repeatable lengths. The parison length is part of the process parameters, which leads to more process reliability. The parameters of every product can be stored as recipe.

| Technical Specifications: | |

|---|---|

| cycle time: ca. 10–30 sec per product side | |

| tube diameter: 0.7–10mm | |

| neck down diameter: 0.6– 7.5mm | |

| 1 linear guide and servo drive 3Nm → max. pull force 1500N | |

| max. linear movement: 455mm | |

| linear travel speed: 1–500mm/s | |

| sensor measurement for reproducible parison length | |

| process temperature: 20–200°C (68-392°F) | |

| user interface with BW-TEC HMI on touchscreen | |

| PLC Controller and PC for HMI and Data management | |

| network compatible | |

| air pressure: 6–8 bar (87–116 psi) | |

| power: 115/230 VAC 450W | |

| dimensions (L x W x H): 1100 x 700 x 560mm | |

| weight: 90kg | |