info@bwtec.com +41 44 863 70 70

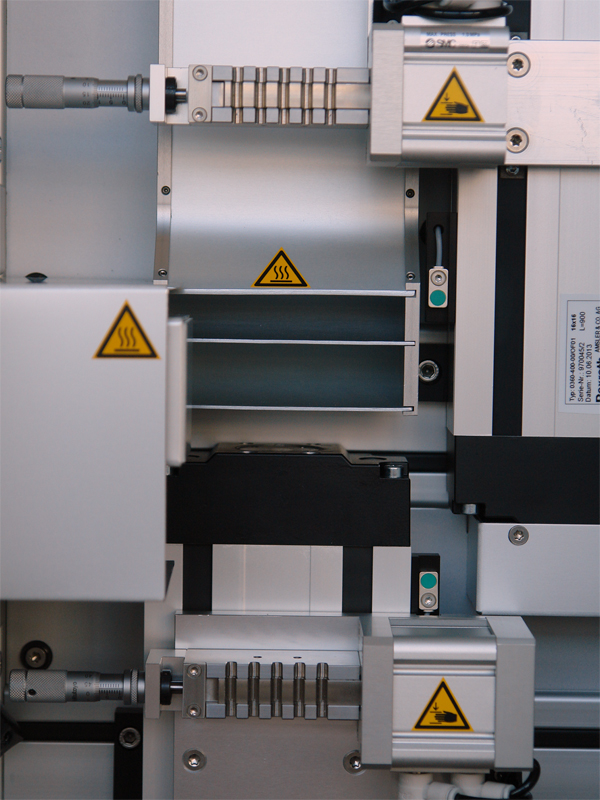

2105 5UP VERTICAL NECKING MACHINE

2105 5UP VERTICAL NECKING MACHINEDownload .pdf

The Vertical Necking Machine is designed to neck down balloon tubes.

This process step comes prior to the balloon forming process. The target is to reduce the tube diameter beforehand in order to eliminate the calibration process after balloon forming. The tube is heated partially by a specifically designed air nozzle and the diameter is reduced by axial moving of two linear slides with different speed and travel.

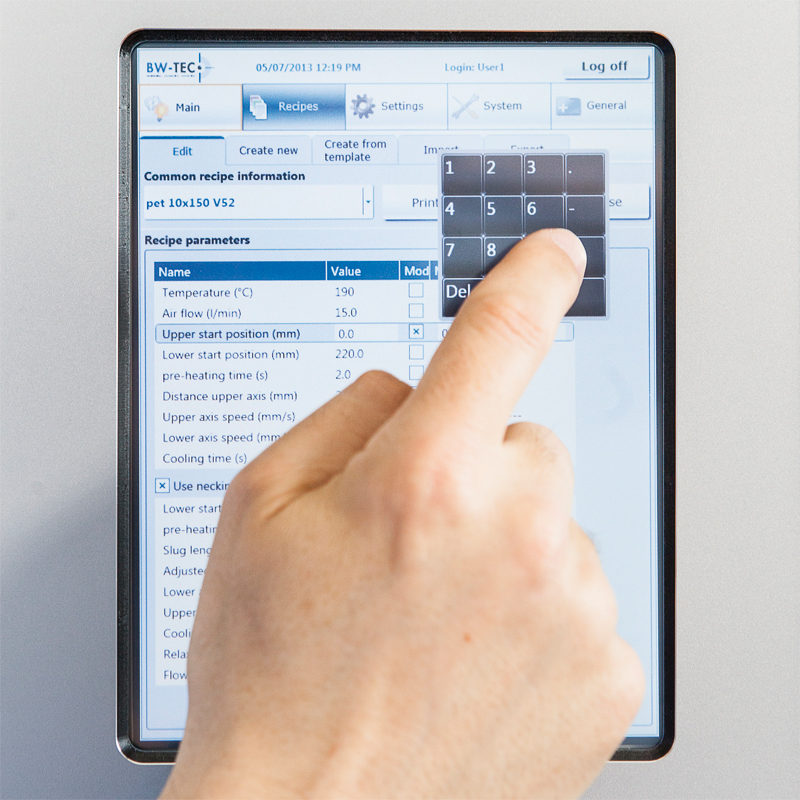

The final diameter of the tube can be changed by adjusting either temperature, speed, travel or relative motion of the two axis.

The parameters of every product can be stored as recipe in order to achieve reproducibility.

| Technical Specifications: | |

|---|---|

| Up to 800 tubes per shift | |

| Process time: | 1–3 min |

| 5-up Machine | |

| Tube diameter: | Ø 0.4–3.5 mm |

| Pneumatically actuated clamps | |

| mass flow controller: | 0- 50 nl/min |

| 2 Linear slide with ball screw spindle and 3Phase stepper motors with 4 Nm | |

| Axial force | 1500 N |

| Travel distance: | 800 mm |

| Travel speed: | 1–150 mm/s |

| Process temperatures: | 20–250° C |

| Heating time: | 0–30 s |

| Cooling time: | 0–60 s |

| air pressure: | 6–10 bar (87–145 psi) |

| simple user interface with BW-TEC HMI on touchscreen | |

| Safety light curtain | |

| PLC controller and PC for HMI and data managment | |

| network compatible | |

| dimensions (L x W x H): | 700 x 600 x 2200 mm |

| weight: | 120 kg |

| power: | 115/230 VAC 1600 W |