info@bwtec.com +41 44 863 70 70

Rapid Heating Block for Accelerated Balloon Forming

Rapid Heating Block for Accelerated Balloon Forming

Making the most out of your BW-TEC Equipment

Playback webinar from Thursday November 02, 2023:

Step into our lab and hear from our engineer on the new BW-TEC Rapid Heating Block that improves the quantity and quality of your balloon production. It is a game changer! Join us and learn how your organization can reap the benefits of reduced Balloon Forming cycle times and increase the temperature distribution and uniformity.

Benefits of the BW-TEC Rapid Heating Block

- Increased Balloon Quality & Quantity

- Reduced Heat up Time by up to 50%

- Reduce overall process time by 40%

- Enhanced Heat Uniformity on Long Heating Blocks

- Reduced temperature difference from 8 to 2 degrees

- Backwards Compatible for 1800, 2530, 2550, 1555 BFM

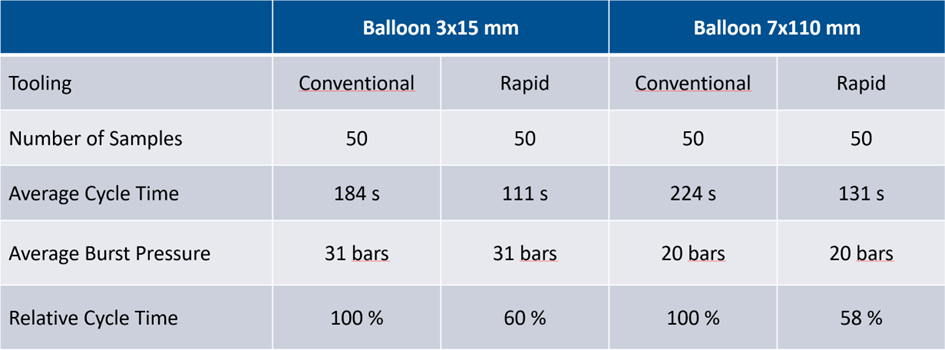

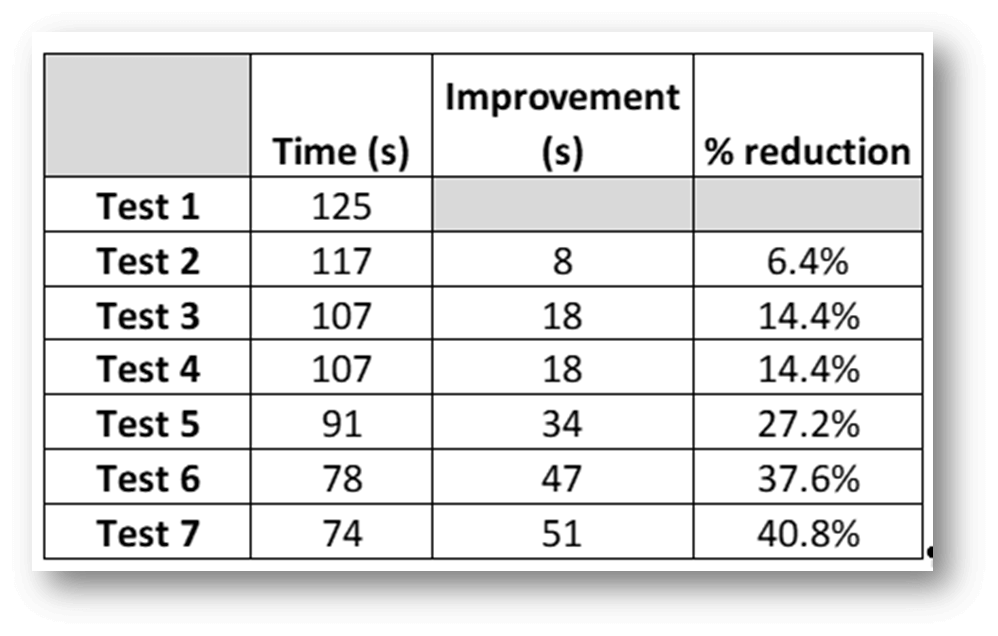

Test Results from Customers with BW-TEC Rapid Heating Block

Customer A:

Customer B:

Q&A

Q: Is it possible to rework existing heating blocks to the Rapid Heating Block?

A: No, that is not possible.

Q: Can I use the Rapid Heating Blocks only on the newest Balloon Forming Machines or also on older systems?

A: The Rapid Heating Blocks are backwards compatible for 1800, 2530, 2550, 1555 BFM.

Q: What material are you using for the Molds?

A: Ampcoloy 940 – please refer to the BW-TEC Balloon configurator for the datasheet.

Q: The Rapid Heating Block reduces the heat up time significantly, does it also improve the cooling time as well?

A: Yes, as the material has better conductivity, the cooling process is also improved.

Q: The Rapid Heating Block improves the temperature distribution significantly, does that have an influence on the balloon quality?

A: Yes, it has an influence on the uniformity of the overall balloon and specifically on the wall thickness.

Q: Does the Rapid Heating Block improve all steps in the forming process?

A: The balloon molding process consists of various steps. The length of some steps in this process is determined by the extrusion properties of the balloon material (forming, stabilization). That is the main drive for the process time and those steps need the same time whatever equipment and system. The heat up times and the cooling time are improved by the Rapid Heating Block.

Q: What has been done regarding process optimization and is it safe to overshoot the temperature in the heat up time?

A: Several measures have been looked at, which are describe in the White Paper in detail. One big influence has certainly optimized PID parameters. It’s safe to overshoot the heating block temperature to a certain degree, for the temperature evolution in the parison is damped by the heat transfer to the product. It’s helpful to measure the temperature inside the parison/slug for optimization.