info@bwtec.com +41 44 863 70 70

BW-TEC HMI

BW-TEC HMIDownload .pdf

The BW-TEC HMI has been programmed for Windows and optimized for touchscreen applications. The HMI can easily be translated into any language without any expense to the programming.

User Interface:

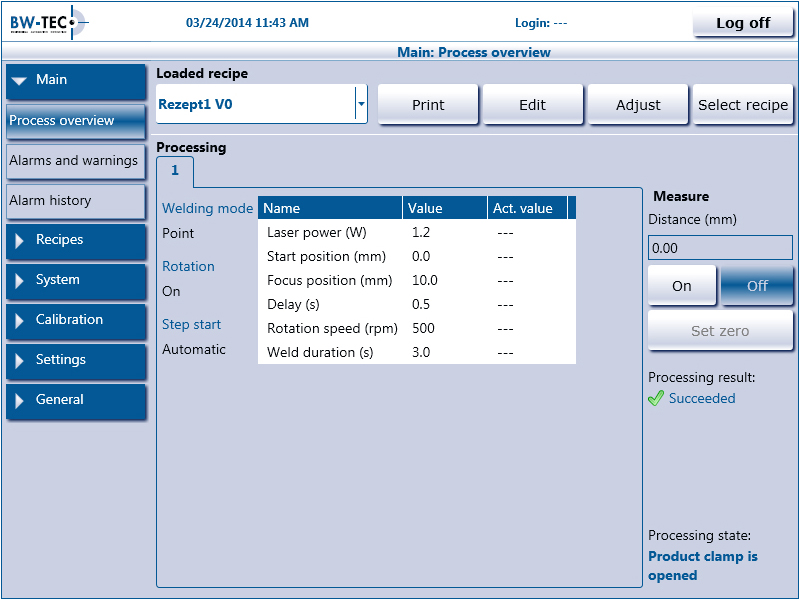

The user interface is designed to be intuitive and simple.

Recipes with multiple parameters are clearly displayed and easy to use and adjust.

With numerous open interfaces, the HMI can be integrated in company-wide ERP and MES systems.

Recipe Management:

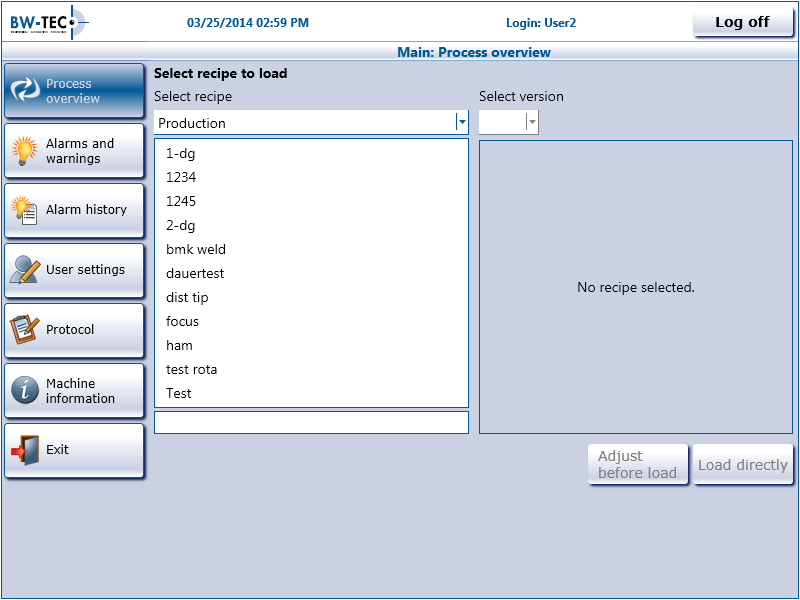

Recipes can be generated directly at the machine or offline.

Multiple recipes can be stored and different storage locations are possible.

Recipes can be easily imported or exported as XML files or within a recipe database.

If a recipe is changed, the HMI will automatically generate a new version.

Modes:

In system mode, all machine components can be controlled manually.

In calibration mode, the machine can be easily calibrated. This mode will only appear for authorized users.

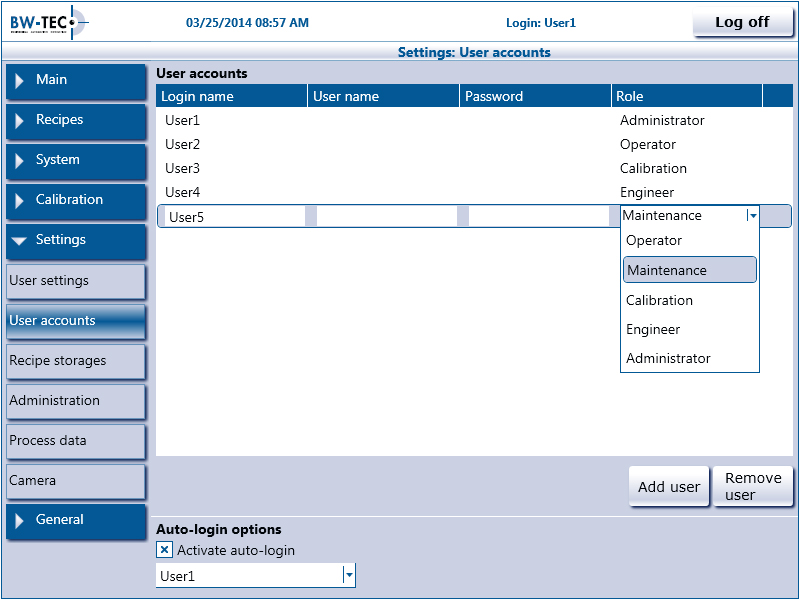

User Administration with Access Control:

Each user can be restricted in their role. For example, only a user with the role “engineer” can generate recipes.

The recipe management will automatically disappear for all other roles.

Operator View:

An operator can only adjust recipes if the engineer has defined an adjustable range.

The user interface for the operator only contains the elements that are necessary for production.

Process Visualization:

The visual representation of the process can be displayed in the form of a table or a graph.

The table displays the current step the process is on.

Different parameters of the graph can be selected. Each graph is stored for reference and interpretation after the process.

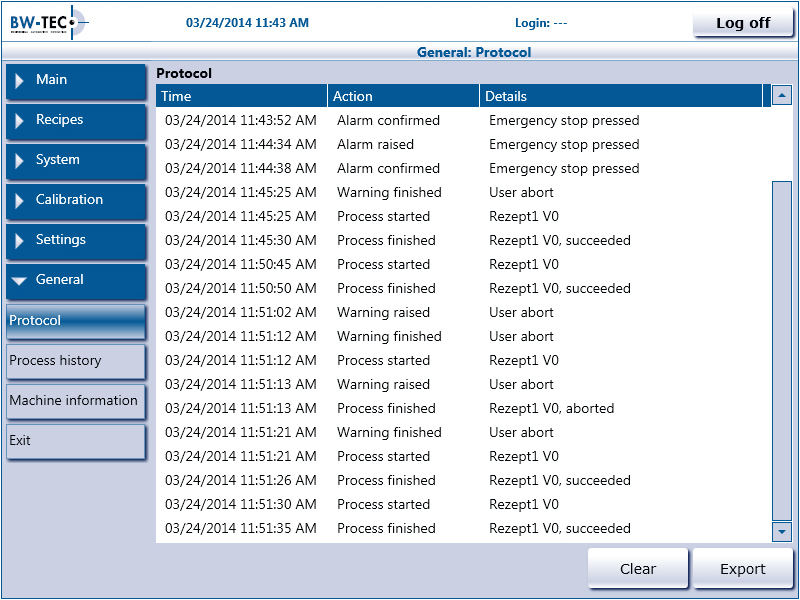

Protocol:

The protocol will show important events, such as process start, process end, logons, logoffs, alarms and warnings.

Process Documentation:

At the end of a process, all data including the user, parameters, and results can be saved in an Excel or XML file or sent to a printer.