info@bwtec.com +41 44 863 70 70

1410 LASER WELDING MACHINE

1410 LASER WELDING MACHINEDownload .pdf

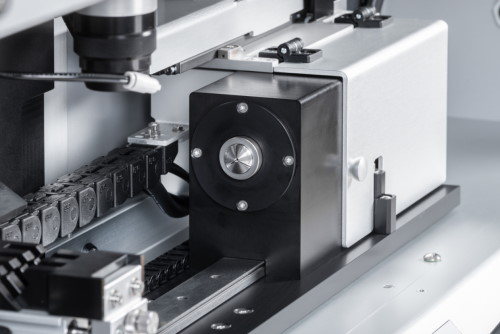

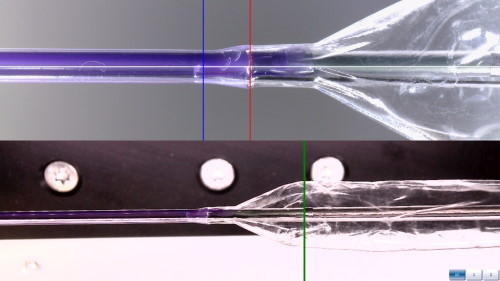

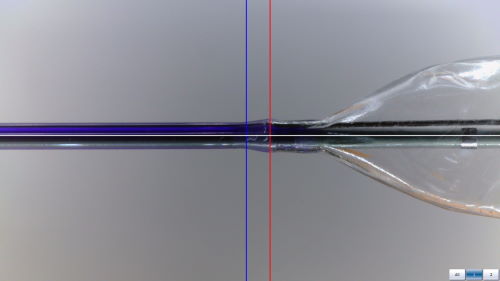

The 1410 Laser Welding Machine is used to connect fine plastic tubing. This machine is ideal for welding of balloon catheters. This connection technology allows short, soft and flexible weldingconnections without endangering the balloon by

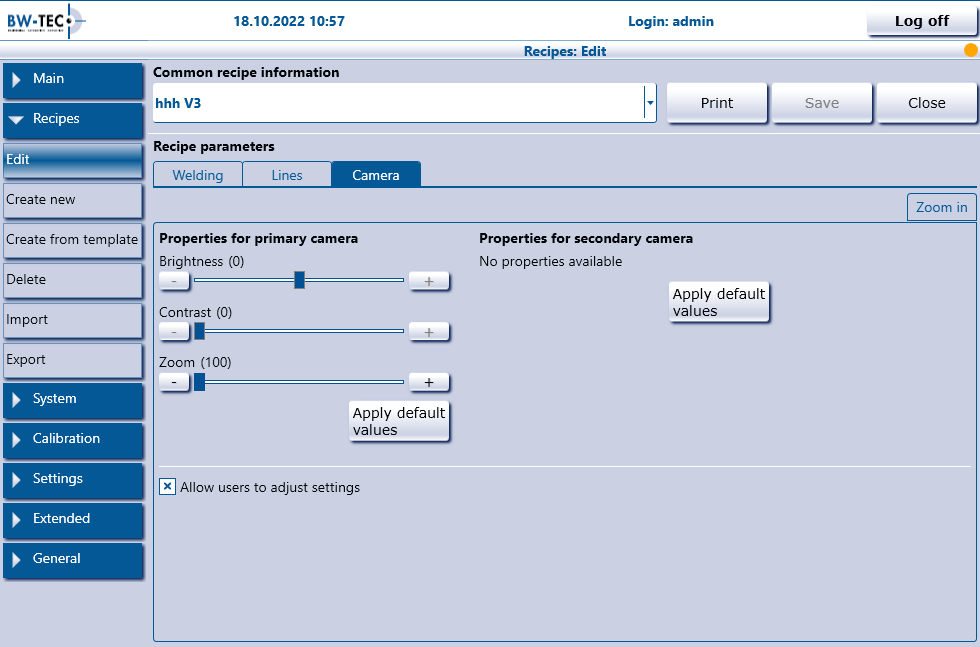

radiating heat. The result is precisely reproducible. The high-resolution camera with zoom option, makes the positioning of the products easy and accurate. The focus position can be changed during the process, allowing for tapered welds and

tip forming.

The product is easily accessible and close to the operator. All movement axes are highly accurate and the machine is optimized for quick and easy maintenance. The touch screen user interface enables process data and user management.

Options

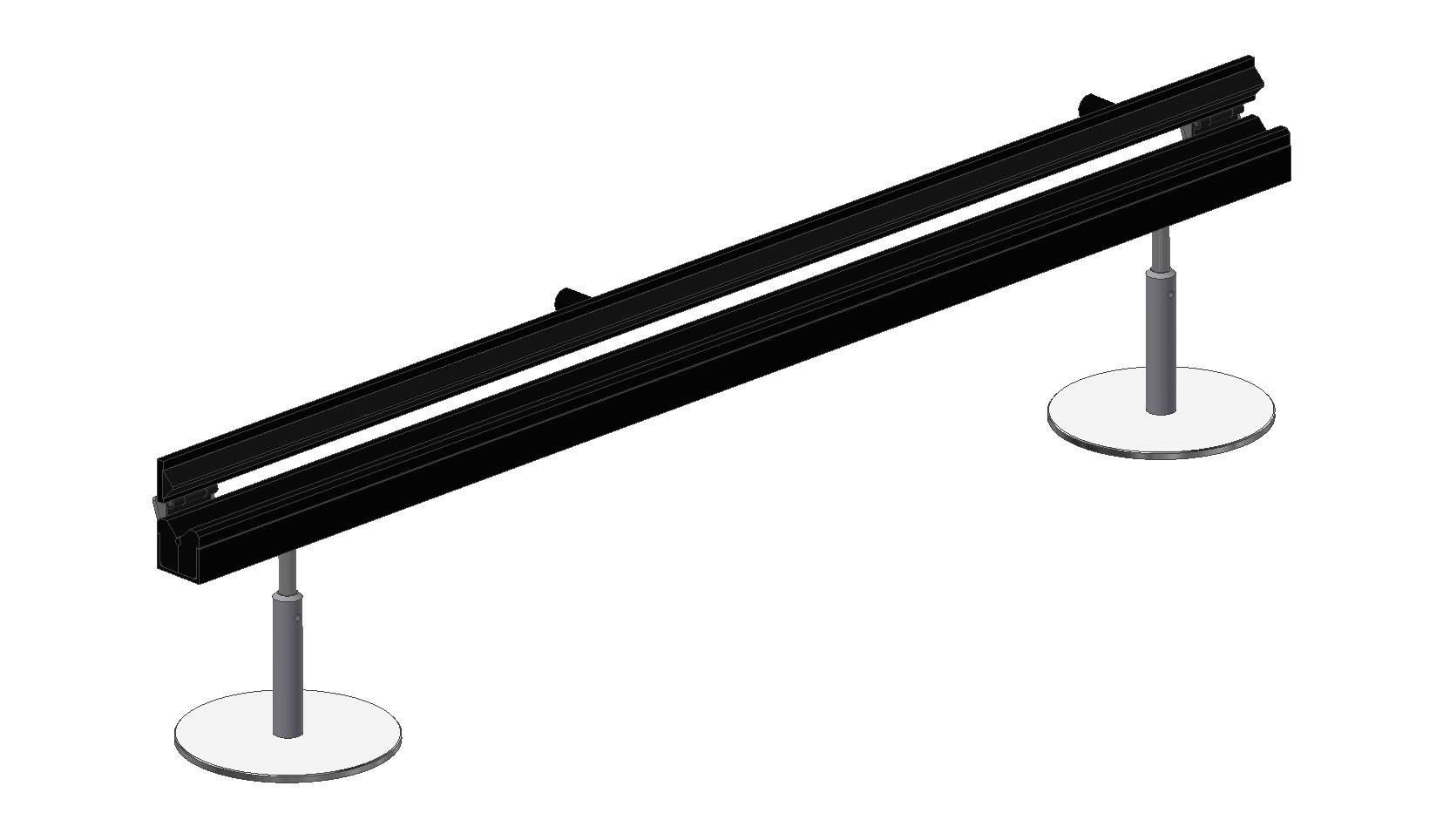

Option Guide Extension: free standing 1000mm with hinged cover

Option Swing or Pendulum: Drive X-Axis

Second Camera: external camera for simplified alignment and positioning of the product using the marker bands.

Work Order Management: The optional software package "Work order management" for BW-TEC HMIs is used to tag the process with work order relevant data like material number or batch number. This package ensures the traceability of the process.

OPC database connection: OPC database allows for easy communication and connection of the machine to the company database.

| Technical Specifications | |

|---|---|

| BW-TEC HMI touch screen | |

| parameters to set: power, welding time, rotation speed, focus position, distance | |

| data storage and network capability with integrated PC | |

| parameter management with customisable reference lines | |

| manage authorisations and access rights | |

| digital camera for active inspection, screenshots and film of production process | |

| air cooled CO² laser | |

| wave length 10.57 to 10.63 μm | |

| power output 5/10 W | |

| power stability +/–2 % | |

| closed loop controller/stabilizer | |

| spot diameter variable 0.2– 4.0 mm | |

| adjustable focus distance | |

| headstock with pneumatic collet closer for collets Ø 0.4–5.0 mm | |

| linear slide with removable product fixture travel x-axis 350 mm | |

| dimensions (L x W x H): 1000 x 504 x 860 mm | |

| weight: 100 kg | |

| power: 100–230 VAC, 50/60 Hz, 700 W | |

| air pressure: 6–10 bar (0.6–1.0 MPa) |